Jack Orrell-Mcleod, Applied Science

Abstract

Plastic waste is one of the largest threats to modern-day society, with little ways to counteract a waste product that has very few sustainable and recyclable uses and often ends up polluting our environment. However, new experiments with roads made of recycled plastic have proved to provide a potential solution to the issue, while also solving another major world issue in connecting our world, with large amounts of resource consumption and pollution stemming from the creation and placing of asphalt roads. Plastic roads could present a solution to a major world problem that is sustainable and additionally cuts down on resources that could be spent on other world issues. To test the potential success of these roads, a makeshift sample of plastic and asphalt were tested with 7 varying situations the samples may encounter while in actual use. The results were a surprising balance between the two, with one sample excelling in areas the other failed.

Plastic waste is one of the modern world’s largest threats to the health of the planet and its inhabitants. Unfortunately, despite the multiple recycling programs around the world, as well as the increasing global efforts to contain the waste, plastic waste is still filling landfills, oceans, natural habitats, and animals. To combat this threat, multiple solutions could be considered and implemented in order to reduce the amount of plastic moving into the environment, including recycling any waste into sustainable and useful products. This experiment was conducted to attempt to explore a possible solution to this pressing problem, which lies in the road materials that make up the transportation network that connects our world.

Roads, the large structures that cover approx. 64,285,000 km (Loisy, 2019) of the world’s surface are good for transporting people and products from one place in the world to another, but the materials that they are made of are not very sustainable. Asphalt roads are made of an aggregate of sand, gravel, and crushed rocks, held together with a tar-like substance (Salah, 2007) that consumes a sizable amount of resources to produce. Further, asphalt creates a large amount of environmental pollution in its production by releasing toxic gases from keeping the mixture at a high temperature and from residues that are usually washed off in the first few rains the roads experience (Aexcel, 2017). Possible recycled options are demolition debris and construction scraps, but the larger issue comes from the binding material. This substance is bitumen, a thick and sticky petroleum product covers the top of the asphalt and is the layer most who use the roads see. However, there are problems with this current road, like alligator cracking that results in damaging potholes and low road quality, and road leaching which results in the toxic bitumen layer moving into the environment, where it can cause damage to the environment and its inhabitants. The goal of a recycled plastic road is to be at least somewhat more sustainable than an asphalt road in order to be suitable for replacement, with less pollution in its creation, placement, and use, with easier placing methods and without creating larger disruptions to traffic.

The model for this recycled plastic road would be a large, hollow piece of road that can be used like a Lego brick with its modular ability. These pieces have a hollow core for piping and electrical systems, with a textured surface to allow tire grip, and be made out of fully recycled plastic that could be sourced from anywhere. These plastic roads can also be constructed in a matter of days, not weeks or months, and will last three times as long (Plastic Smart Cities, 2018) (Plastic Road ,2022). This allows for large amounts of recycled plastic to not go to waste, and instead be used as a material that is often taken for granted but is essential for human transportation. In turn, this new road can save on resource consumption and pollution by avoiding the need for the processing production normal roads require, as well as removing the need for bitumen, which can cause several environmental hazards from its production and usage. Plastic roads can be laid down in a matter of hours, and create a smooth and safe surface, unlike the signature bounciness that asphalt roads get when they are paved unevenly or inconsistently along the road.

Worth mentioning is the bases for these roads. A road is only as strong as its foundation, regardless of its quality. A base that can be washed away by disasters such as floods can compromise the structure of the road atop it. ((Gulseven & Mostert, 2017) Gulseven, 2019) Asphalt roads have an aggregate base that the asphalt (material used for this experiment) sits atop of. Plastic roads don’t have a separate base that asphalt roads have, instead they consist of a hollow structure with plastic on all four sides, which can allow for piping and electrical systems to be run through them. While a hollow road piece can prove to have issues, with proper internal reinforcement and thick plastic layers to keep the outside of the plastic from getting to the inside, plastic roads can be strong enough to handle disasters in ways that asphalt may be inferior to.

Similar experiments are currently being conducted by other companies that are looking to apply these designs to modern roads. While their tests are still in early phases, promising results are being recorded. Two examples of current pilot projects are being undertaken by Plastic Road and Plastic Smart Cities who have launched their first phases of testing. (Plastic Road, 2022) (Plastic Smart Cities, 2018)

Materials and Methods

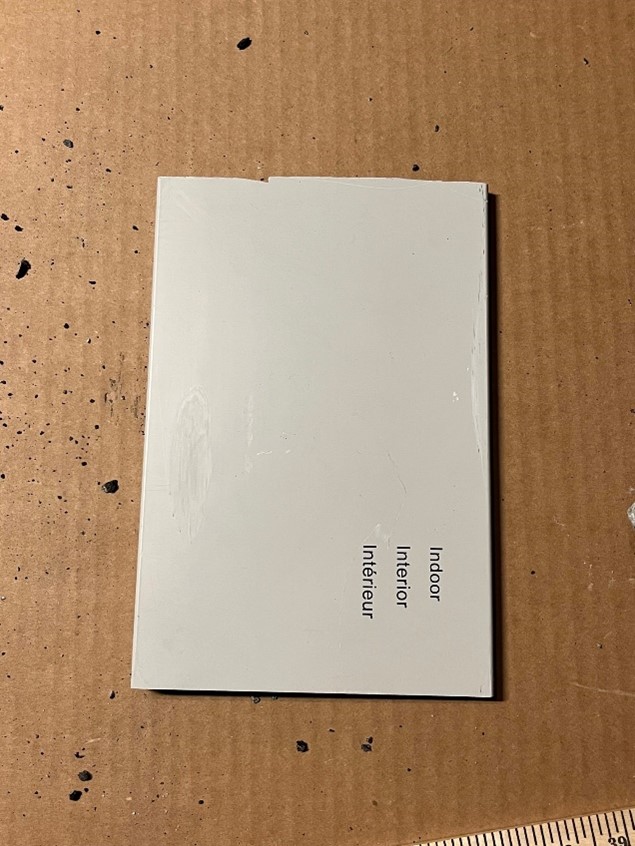

In order to test asphalt and plastic, a series of tests was devised that would test a sample(s) of asphalt (fig.1) and plastic (fig.2) road to determine if they would function under conditions that they would likely experience while in use.

Figure 1. Two samples of asphalt. The one on the left will be used for the impact test, while the one on the right will be used for the heating/cooling test.

Figure 2. A sample of plastic used in this experiment. This sample is going to be used for the impact test.

The goal was to test the durability of each element while being within the same magnitude (ex. 25 pound rock dropped from same height onto each sample under exact circumstances). The tests were as outlined in Table 1: Each test was conducted twice to collect a more detailed and thorough set of data.

Table 1. Tests Performed on Asphalt and Plastic Road Surfaces

| Test Title | Method | Duration | Purpose |

| Long-term Weathering | Two samples of road are left outside. | Two months | Determine impact over time due to typical local weather patterns |

| Long-term static | Two 25-pound weights are applied to the surface of two samples of road | Two months | Measure the impacts of a vehicles or other heavy objects resting upon a road |

| “Treadmill Grind” | Two samples of road were pressed with considerable force against a moving abrasive belt of a treadmill. | 2 and a half minutes for each sample | Test the resilience of the roads if a similar heavily abrasive situation occurred on the road, like a crash or landslide across the surface |

| Thermal Resiliency | Road samples are heated with a heat lamp, then dramatically cooled in a freezer. | 20 minutes for heating/cooling | Simulate temperatures the roads may experience |

| Continuous Force | Drill with a very large bit (5/16) was used against samples. | 15 seconds | Simulate a heavy force being applied to the road surface, similar to a accident |

| Impact | 1 pound, then 10 pound rock was dropped from 1 meter onto the two samples individually | Instantaneous | Simulate debris impacting the road |

Long-term weathering, where two samples of road are left outside to weather the elements for two months.

Long-term static test: a similar experiment, where two 25-pound weights are applied to the surface of two samples of road, and left for two months to measure the impacts of a vehicles or other heavy objects resting upon a road.

A “treadmill grind,” where the two samples of road were pressed with considerable force against a moving abrasive belt of a treadmill, in order to test the resilience of the roads if a similar heavily abrasive situation occurred on the road, like a crash or landslide across the surface.

A thermal resiliency test, where both road samples are heated with a heat lamp, then dramatically cooled in a freezer to simulate temperatures the roads may experience.

A continuous force test with a drill with a very large bit (5/16) to simulate a heavy force being applied to the road surface, similar to the static test but with a much shorter time.

Finally, an impact test, where a 10 pound rock was dropped from 1 meter to simulate debris impacting the road.

These experiments were all to test a scaled-down version of various weather conditions these roads would face while in use. It is expected that both roads would be able to hold up to these conditions with minimal damage, as they would be facing these conditions periodically while in actual use.

Results

All tests had extremely similar or identical results, providing the evidence of what happened as being the most likely result in that specific situation.

The experiment’s results were as follows:

Long-term weathering: The asphalt did not experience any major degradation or impact that would render it unusable. Small pieces were washed from the surface layer of the asphalt, forming a sandy layer around the asphalt that contained grains no larger than peas. The main body of the asphalt was unaffected, with no visible cracks or destabilization detected. The plastic had no visible change. No cracks or bends were found. However, a very small amount of whitish residue was left around the plastic, similarly to the asphalt (fig.3). This is evidence of leaching from the plastic due to the elements, which is something that should certainly be noted in comparisons, as similar leaching from bitumen roads causes environmental pollution. Plastic pollution is the very issue we are trying to solve, so this leaching could prove counterintuitive if the plastic recycled into the road is simply washed out during rains. It is possible the model of plastic may be the source, and different plastic compositions could be used to deter this leaching, however such models cannot be investigated in this report due to time constraints.

Figure 3. The Residue from the Long-Term Weathering Test

Long-term static

The asphalt experienced very little damage, other than an even further minimality in residue, with only a miniscule amount of sand aggregate being present around the site of direct weight pressure and around the base of the asphalt. No cracking or other signs of degradation were found on the asphalt. The plastic had a slight bend where the weight had rested, but otherwise had no sign of damage. This is noteworthy, as the weight was placed atop the plastic, with an air gap between the plastic layer and the ground, which would be how a fully-scaled plastic road would function. It is to be noted that when the experiment was repeated with no air gap between plastic and ground, no bending or deformation of any kind was found.

Treadmill/abrasion grind

The asphalt had no significant cracking or damage, but had a good amount of aggregate sand and gravel particulates removed from the surface of the asphalt. A handful of black sand-like aggregate was released from the asphalt, along with many pea-sized and smaller pieces of asphalt and gravel. The surface that had been applied to the treadmill had also visibly smoothened, which could easily be felt. Despite those impacts, no cracking or destabilization had occurred. The plastic had much less damage, with only a visible amount of scratches present on its surface. This is also noteworthy, as these scratches were both visible to the eye and easily felt by touch. It is possible that such texturing could in fact improve the coefficient of friction between cars that use this hypothetical road and its surface. Asphalt has a higher coefficient of friction than plastic, which could cause less grip for cars on the road. This is similar to hydroplaning, where a layer of water causes tires to lose their grip on the ground and can cause loss of control and accidents. (Zhao, 2017) (fig.4).

Figure 4. The scratches slightly visible on the plastic post-test

Heating/Cooling test

The asphalt was warm to the touch when warmed by the heat produced, which did not visibly expand the material, but when placed in a cold environment, produced small visible cracks around the edges of the asphalt, as well as producing a small amount of residue in the form of small pieces of surface asphalt breaking off from around the main piece. Some pre-existing cracks grew slightly larger. The plastic piece was warm to the touch when warmed. It did not melt but did become more flexible. When cooled, it became much more rigid once more. This experiment proved that both materials are not immune to the effects of heating/cooling, and may require asphalt roads for some places in the world. While the plastic road samples merely became more flexible, it is more than likely that higher temperatures may cause the road to melt, which can result in numerous complications. The road will likely be able to withstand moderate temperature fluctuations, but in more temperature-extreme areas of the world, this might not be possible, thus requiring asphalt roads in few places.

Continuous force test

The asphalt had a small amount of material removed from its surface, primarily from the sides where the bonds holding the asphalt together was loosened. The main body of the asphalt, however, held together, albeit with a few more cracks along where the drill had impacted the asphalt. The plastic had almost no negative effect, other than a loud noise being produced from the impact and the surface of the plastic being slightly scratched from the bit’s tip. This is a good sign that plastic roads would be able to withstand debris and vehicle collisions upon its surface, which would extend its warranty before replacement.

Impact test

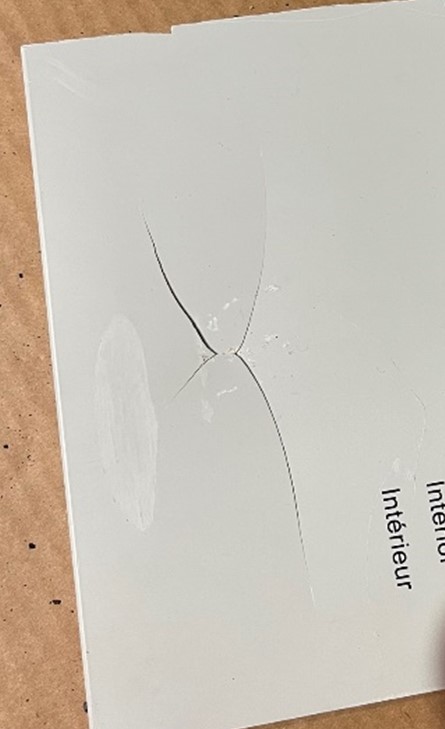

Two different-sized rocks were each dropped on the asphalt and plastic pieces to simulate debris or other impacts on the roads. The small rock had no considerable impact on the asphalt, other than a very small chip on the surface of the asphalt (fig.5). The larger rock, however, broke the asphalt apart into two pieces, with multiple much smaller pieces also being chipped off, all on the region of the asphalt cracks (fig.6). A small amount of black aggregate sand was also released. Interesting details to note were the facts that not only had the break not formed from a previously existing crack, but at a glance within the asphalt, small gravel-rocks were seen split in half. The plastic had a similar reaction to the rocks that the asphalt did. The first rock had minimal damage, with only a small mark where it had impacted the plastic. The second, heavier rock had a similar impact on the plastic, with a large break being created in the plastic, with four smaller cracks spiderwebbing out from the main break (fig.7). An interesting note would be that this break occurred with the space beneath where the break occurred, and when the experiment was repeated with the plastic having no space between the rock and the ground, a much smaller crack was produced, with much smaller spiderwebbing cracks.

Figure 5. Asphalt sample after impact from small rock

Figure 6. Asphalt sample after impact from large rock

Figure 7. Plastic after impact from large rock (small rock produced no noticeable result).

In most regards, the plastic outperformed or performed similarly to the asphalt. However, while the plastic outperformed in most regards, any damage it did sustain were sources of potential further inquiry. The long-term test yielded mild damage and leaching from the asphalt, with only a very small amount of leaching from the plastic. The asphalt had slight degradation from the weight upon it, with only a mild bend from the weight upon the plastic. The abrasion test yielded an amount of particles from the asphalt, as well as visible smoothing, while the plastic sustained only small scratches on its surface. The heating/cooling test produced a small amount of damage in the form of shedding from the sides of the asphalt and widening of cracks, while the plastic became more flexible while warmed. The continuous force test yielded small cracks and a small amount of degradation from the asphalt, while only scratches and noise were present on the plastic. The impact test yielded minor damage with the small rock, but catastrophic damage with the large one, with the asphalt piece breaking in half, and the plastic receiving a large break in its surface, although it is noteworthy that the impacts on the same pieces were much less severe with no space beneath the plastic and solid ground.

Discussion

With the evidence gathered, there is good evidence to consider that in a few areas, the plastic is an improvement over asphalt, with generally positive results being displayed in the long-term weathering, abrasion test and continuous force test. However, there are still many variables that make plastic arguably inferior in certain conditions, such as the heating/cooling test and the impact test, and may require plastic roads to be refined or simply skipped over in a situation where roads are much more environmentally friendly and less toxic. For example, the samples of asphalt and plastic may vary according to the places that used them. Such changes like the texturing discovered in the abrasion test by creating more tactile surfaces for tire grip, and a thicker plastic road surface, as discovered in the long-term static test, could improve these roads to be more all-purpose and would be able to be installed in various places around the world with more extreme weather conditions. The plastic pieces used in the experiment were not initially meant for road tests, belonging to the spare parts list of an air conditioner. The asphalt was sourced from scrap pieces found on the sides of roads or from previously used roads, therefore likely already being compromised and not the most fit for testing. The pieces used are also from various locations, so their level of quality could differ across experiments, especially if the asphalt pieces were used again for other tests, which would result in already partially compromised pieces. If the experiment were to be repeated, it would likely be using actual samples of asphalt and plastic roads, and with many more tests, and likely full-sized models undergoing actual road tests instead of improvised ones with drills and small rocks. It is safe to say that any viewer should take these results lightly, as much further inquiry must be made before a conclusive decision can be made.

References

Abraham, G. (2015, December 18). Plastic Roads- A Revolutionary Idea. Recycleinme. https://scrapnews.recycleinme.com/newsdetails-295.aspx

Barnett, Kelly. “From Waste to Wonder: The Road Made Entirely of Recycled Plastic.” Orbia, Orbia, 4 Jan. 2021, https://www.orbia.com/this-is-orbia/news-and-stories/plastic-road/.

Circular, climate-adaptive, and Lightweight. PlasticRoad. (2022, August 5). Retrieved November 16, 2022, from https://plasticroad.com/en/

El-Haggar, S. M. (2007). Asphalt mixture. Asphalt Mixture – an overview | ScienceDirect Topics. Retrieved March 30, 2023, from https://www.sciencedirect.com/topics/engineering/asphalt-mixture#:~:text=the%20base%20layer.-,Asphalt%20mixtures%3A%20Asphalt%20is%20a%20mix%20of%20sand%2C%20gravel%2C,density%20of%20the%20mixture%20increases.

Gulseven, O. (2019, October 2). A sustainable model for enhancing road quality with recycled plastic bags | Kuwait Journal of Science.

Plastic Smart Cities. (2018, September 11). Plastic road. Plastic Smart Cities. Retrieved November 16, 2022, from https://plasticsmartcities.org/products/plastic-road

Trimbakwala, A. (2017). Plastic Roads Use of Waste Plastic in Road Construction. International Journal of Scientific and Research Publications, 7(4), 137-139.