Davan Mulligan, Year 2 Research

Abstract

Plastic pollution is a growing problem the world faces, as it litters our world and natural environment. Plastic is used in many people’s daily lives and has many uses and applications. In this project, starch bases were compared in production of eco-friendly biodegradable plastic substitutes. Cornstarch, wheat starch, potato starch, and tapioca starch were used as bases for the bioplastics in this experiment, and the products were tested for strength. It was found that the bioplastic made from potato starch was the strongest, while the wheat starch bioplastic was the weakest viable plastic.

Introduction

Traditional (petroleum-based) plastics have a wide variety of applications, and play a significant role in people’s day to day lives (Marichelvam et al. 2019). As a country, Canadians produce 3 million tonnes of plastic waste annually (Government of Canada 2020). According to the Canadian government, only 9% of plastic in Canada is recycled, with 29,000 tonnes finding its way into our natural environment every year (Government of Canada 2020). On a global scale, about 359 million metric tonnes of plastic was produced in 2018 (Narancic et al. 2020), and although large-scale production of plastic only began in the 1950s, an estimated 8300 million metric tonnes of new plastic has been produced from the mid twentieth century to date (Geyer et al. 2017). Of the estimated 8300 million metric tonnes of plastic produced since about 1950, only 6% was recycled (Ritchie and Roser 2018). If the world continues to produce and manage plastic as it currently does, by the year 2050, approximately 12,000 Metric tonnes of plastic waste will occupy landfills as well as our natural environment (Geyer et al. 2017).

Starches are abundantly available, biodegradable, cheap, and renewable (Narancic et al. 2020), and they may have the potential to yield an environmentally-friendly plastic alternative. The purpose of this project is to determine a starch base that can produce a strong, biodegradable plastic alternative. In this project, various types of starch was used to determine the most efficient biodegradable plastic alternative, alongside vegetable glycerin, a natural plasticizer (Sen et al. 2017).

Amylose and Amylopectin are the two primary molecules present in starch, with Amylose being straight-chained, and Amylopectin being branch-chained (Sen et al. 2017). As Amylose’s straight-chain structure contributes to its gelling strength, starches high in Amylose will provide gelling properties, whereas Amylopectin-dense starches will provide more viscosity, as the large molecular size of Amylopectin due to its branch-chained structure yields this trait (Hegenbart 1996). The Amylose-Amylopectin ratio of the starches used in this project are as follows: potato starch, 20:80; cornstarch, 28:72; wheat starch, 25:75 (Jha et al. 2019); and tapioca starch, 15:85-18:82 (Hegenbart 1996). In order to isolate starch as the only variable, the same measurements of glycerin and water were used in experimentation of all starch bases. It was hypothesized if the starch was higher in Amylose, then it would be more successful as a bioplastic, due to the gelling properties of the molecule potentially causing the product to be more durable.

Materials and Methods

Creating the Bioplastics

4 ½ tablespoons of one starch was mixed into 400 mL of water and stirred until it appeared completely dissolved. The mixture was then heated on a stovetop, and once boiling, 70 mL of vegetable glycerin was added. The glycerin was stirred into the water and starch, and the mixture was left at a simmer for 5 minutes following the addition of glycerin. It was then spread onto a tray lined with parchment paper and left to cool and dry for a week at room temperature.

Tensile Strength Tests

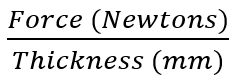

Two strength tests were conducted, both measuring different aspects of tensile strength. For the first strength test (Strength Test A), each bioplastic was secured at each opposing ends to two tabletops as shown in figure 1. Weights were then placed in the centre of the bioplastic and its ultimate strength was measured. Ultimate strength is defined by Collins Dictionary as “the maximum tensile stress that a material can withstand before rupture.” Tensile strength in both tests were calculated by the equation:

Figure 1: Diagram of tensile strength test A

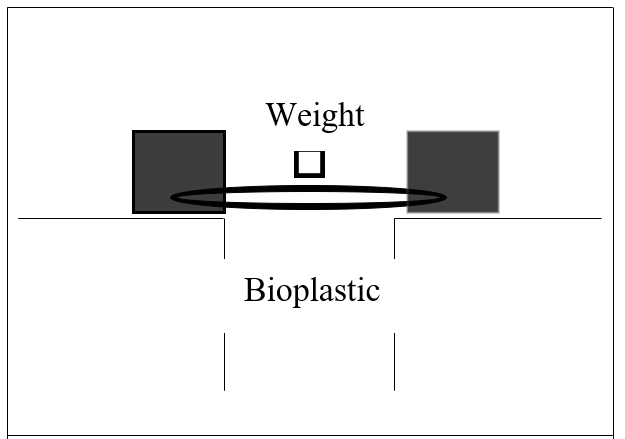

For the second strength test (Strength Test B), each bioplastic was secured at one end by a weight, and, at the opposing end, attached to clips and pulled by a spring balance shown in figure 2. The ultimate strength of the bioplastic was then measured and calculated by the aforementioned equation.

Figure 2: Diagram of Tensile Strength Test B

Results

Strength Test A

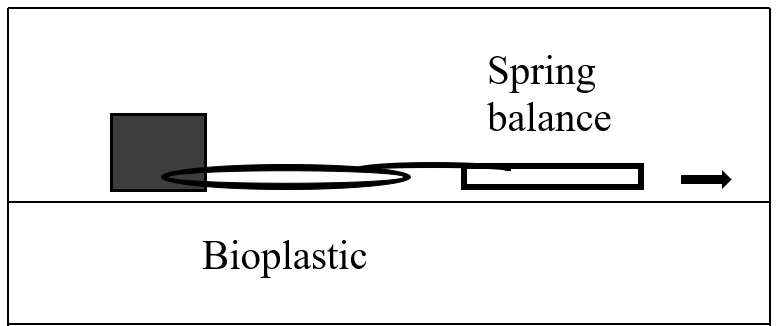

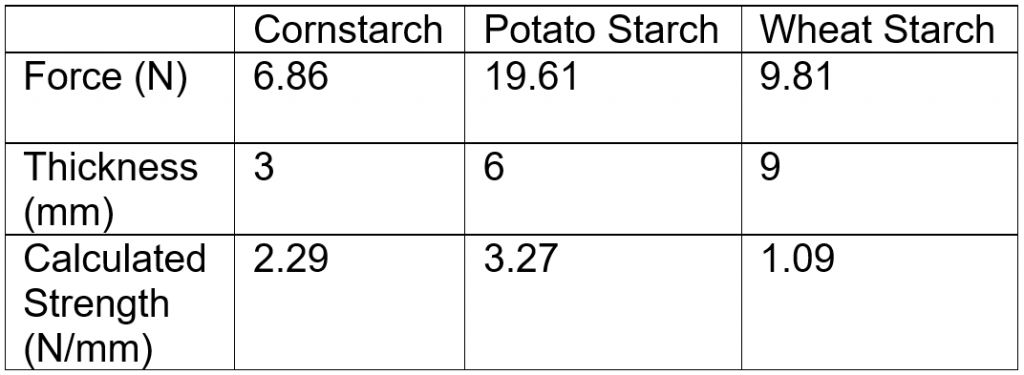

Table 1: Force in Newtons divided by thickness in millimetres

The bioplastic with a potato starch base was calculated to have the highest strength, at 3.27 N/mm, having 0.98 N/mm of strength more than that of cornstarch, and 2.18 N/mm more than that of wheat starch.

Strength Test B

Table 2: Force in Newtons divided by thickness in millimetres

The bioplastic with a potato starch base was again calculated to have the highest strength, at 2.45 N/mm, with 0.65 N/mm of strength more than that of cornstarch, and 1.58 N/mm more than that of wheat starch.

Discussion

Results from both strength tests suggested the bioplastic made from potato starch had the most tensile strength, with cornstarch second, followed by wheat starch. It is important to note that data could not be obtained from the bioplastic made from tapioca starch, as the starch failed to produce a testable result, which is why it was absent from the data tables. The bioplastic made with a tapioca base broke before experimentation could be conducted. It was hypothesized that the starch highest in Amylose would present the best results, however, both cornstarch and wheat starch were higher in Amylose than potato starch, yet potato starch was found to have the highest strength. As the tapioca starch broke before experimentation could occur, it may be inferred that there was not enough Amylose to bind the plastic. Similarly, the wheat starch was the most qualitatively thick and sticky, possibly due to the high ratio of Amylopectin present in the starch, however, further experimentation is necessary before drawing these conclusions.

In future experiments, temperature when producing the bioplastic should be measured and recorded, as different starches may have different temperatures necessary for gelatinization (Abe et al. 2021). Given more time, it would have been beneficial to experiment on the concentration and type of plasticizer used. In this project, 70 mL of vegetable glycerin was used for each bioplastic, although using different ratios and other plasticizers, such as sorbitol, may have provided more insight. Future experiments should include more trials to improve accuracy of data, as only one trial was used for each strength test due to limited time and resources. More variables would also be beneficial to finding a successful plastic alternative, as, plastic has a plethora of uses that were not covered in this experiment. Further studies on different bioplastics should explore the wide variety of uses traditional plastic has, and attempt to create eco-friendly plastic that suits all roles traditional plastic is currently used for.

References

Abe et al. “Advantages and Disadvantages of Bioplastics Production from Starch and Lignocellulosic Components.” Polymers, vol 13, no. 15, July 2021, https://doi.org/10.3390/polym13152484

Geyer et al. “Production, Use, and Fate of All Plastics Ever Made.” Science Advances, vol. 3, no. 7, July 2017, https://doi.org/10.1126/sciadv.1700782.

Government of Canada. “Canada one-step closer to zero plastic waste by 2030.” Environment and Climate Change Canada, Oct. 2020, https://www.canada.ca/en/environment-climate-change/news/2020/10/canada-one-step-closer-to-zero-plastic-waste-by-2030.html.

Hegenbart, Scott. “Understanding Starch Functionality.” Natural Products INSIDER, 1 Jan. 1996, https://www.naturalproductsinsider.com/foods/understanding-starch-functionality.

Jha et al. “Effect of Amylose–Amylopectin Ratios on Physical, Mechanical, and Thermal Properties of Starch-Based Bionanocomposite Films Incorporated with CMC and Nanoclay.” Starch, vol 72, no. 1-2, Jan. 2020, https://onlinelibrary.wiley.com/doi/10.1002/star.201900121.

Marichelvam, et al. “Corn and Rice Starch-Based Bio-Plastics as Alternative Packaging Materials.” Fibers, vol. 7, no. 4, Apr. 2019, p. 32. Crossref, https://doi.org/10.3390/fib7040032.

Narancic et al. “Recent Advances in Bioplastics: Application and Biodegradation.” Polymers, vol. 12, no. 4, Apr. 2020, p. 920. Crossref, https://doi.org/10.3390/polym12040920.

Ritchie and Roser. “Plastic Pollution.” Our World in Data, University of Oxford, 1 Sept. 2018, https://ourworldindata.org/plastic-pollution#citation. Sen et al. “Synthesis and Testing of Corn Starch Based Biodegradable Plastic and Composite.” 8th International Science, Social Science, Engineering and Energy Conference, Pattaya Beach, Thailand, 15-17 March 2017, https://www.researchgate.net/publication/330845696_Synthesis_and_Testing_of_Corn_Starch_Based_Biodegradable_Plastic_and_Composite