Jennifer Zhang, Year 2 Research.

Abstract

Investigating the materials to block certain mechanical waves, such as sound waves, is important for communities because noise can lead to physical or mental health problems. My research question is would the sound intensity level affect the effectiveness of the existing sound-absorbing materials. So, four samples had been chosen (acoustic foam, mineral wool, black-out curtains, and cork underlayment) to be tested at five different sound intensity levels (in dBA). Acoustic foam performs the best in the given set while all the rest have a similar effectiveness. Change in dBA doesn’t affect sound-absorbing effectiveness. Porosity, the number of holes in reference to the volume, is suggested as an important factor in sound-absorption. Another sound-absorbing factor is relevant – irregular surfaces. Further work can explore these two factors more in-depth.

Introduction:

Sound can be categorized as desirable and undesirable. While desirable sounds can vary greatly from person to person, there is a mutual agreement on undesirable sounds, commonly referred to as noise. Noise is commonly regarded as problematic in a communal setting. In a more extreme case, certain noise might be damaging to human hearing (Hohmann, 2015). Hohmann’s (2015) study shows the existence of various noises and the potential severe impact on human’s hearing. Furthermore, research has suggested that noise can be a stress factor, inhibiting human performance (Szalma, 2011). So, there have been studies conducted to develop a way that the noise wouldn’t be presented.

When sound travels through an object, it will lose some of the energy or be converted to heat energy because the object resists the vibration (Hellemans, 2000) action. This process is sound-absorbing. Hellemans’s (2000) article shows that the sound-absorbing mechanism still needs further investigation to develop the effectiveness in more extreme frequency. Currently, sound-absorbing research has two main branches: the material and environmental factors. The material-focused path works on either modifying existing porous and fibrous material tailored towards a specific setting or making a more environmentally friendly version through natural resources. For porous material, 20-22 dB transmission reduction for low and medium frequencies (0.5 – 6.3 kHz) has been achieved with around 15 nm porous fillers (Bardakhanov et al, 2018). Bamboo fibrous material has a 0.4 – 0.9 sound absorption coefficient in 500 – 4000 Hz frequencies. (Nordin et al, 2016) The research question is would the sound intensity level affect the effectiveness of the existing sound-absorbing materials. This research fits in the material category with a focus on affordable and large-scale building usage. So, the materials are chosen based on commonality and affordability. Out of the four materials, only one material – cork underlayment is an eco-friendly material because it is biodegradable.

Material and Methods:

In this experiment, dBA – dB with A weighting – tailored towards how the human ear perceives sound was chosen because it displays a lower value compared to dB at the extreme frequency (db: What is a decibel?).

The two factors tested in this experiment are materials and sound intensity. Four material samples had been chosen: acoustic foam (Unicoco), CF1 mineral wool (Frost King), black-out curtains (Nicetown), 1.2 cm cork underlayment (Forna). Five sound intensity levels were chosen at 60.4 dBA, 70.4 dBA, 76.5 dBA, 80.4dBA, and 85.5 dBA according to the mode measurement of the corresponding sound bars on the phone. They were also in the range from conversation to traffic jam loudness.

Figure 1: Tested Material Placement

Figure 2: Lateral View During Testing

An open lid box with outer dimension length: 24.4 cm, width: 14.4 cm, height: 4.8 cm was built using 1.2 cm thickness cork underlayment (Forna). The frequency was fixed at 432 hertz. All material sample pieces had a dimension of 12 cm*4.8 cm *1.5 cm and was placed on the same 14.4 cm* 4.8 cm marked side and remained there, shown via figure 1. The ULKTL380 decibel meter device (LiNKFOR) was placed and touched the phone’s speaker (use figure 2 as reference). The number was read from the decibel meter device and was checked less than ∓ 1.5 dBA (device accuracy) compared to 60.4 dBA. Next, the box was flipped upside down and was slid in between the speaker and the device. Pressure had been applied to the box to minimize air holes. The speaker, box, and device remained in contact with each other. The data was read from the display once the number stabilized for more than three seconds to be considered as valid measurement. Then the measurement procedure was repeated two more times. After these three measurements, the measurement procedure was repeated with 70.4 dBA, 76.5 dBA, 80.4dBA, and 85.5 dBA. Next, all the decibel measurements were repeated with each material (including control).

Results:

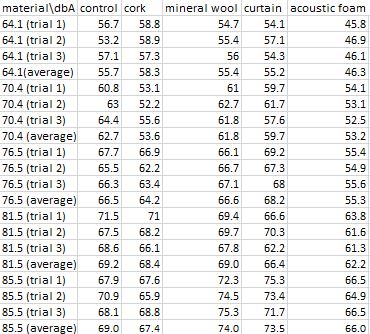

Table 1. Raw Tested Data Point Organized by Sound Intensity Level in x-axis and Material in y-axis

As table 1 has shown, there are five material data sets tested against five different sound intensity levels. Since the question is material effectiveness, the reduced percentage of sound intensity is the desired portion. To obtain the reduced percentage, use (original dBA – tested dBA)/original dBA *100%.

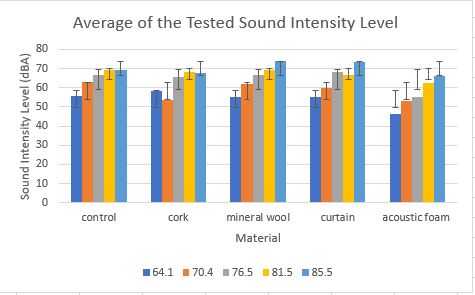

Figure 3. Average of the Tested Data Points

In figure 3, the data points from each section were taken to find the average in that category. As displayed in figure 3, it has an overall increasing trend (as dBA increases, the tested dBA increases as well). However, for cork in 70.4 dBA, it significantly breaks the staircase pattern. Then, the reduced percentage was obtained.

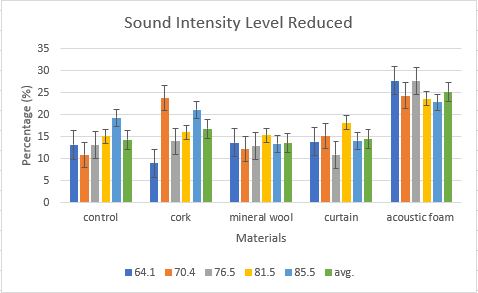

Figure 4. Sound Intensity Level Reduced in Percentage Grouping by Material

In figure 4, the material was sorted by category to see if there is a certain trend or pattern within each material. Most of the group’s reduced percentage lies around 15%. Acoustic foam performs significantly better than other materials with an average of 25%. Most of the groups show the trend of the horizontal flat lines because of similar heights. For example, the mineral wool and acoustic foam group have less than a 5% difference between the biggest and the smallest. On the other hand, cork has the most inconsistent, having a 20% difference. In the average data set cork at 70.4dBA already shows an obvious outlier to the overall trend, in the reduced percentage it is magnified. Also, the control, mineral wool, and curtain group are very similar.

Discussion:

This study suggests that the acoustic foam is more effective at sound-absorbing. Acoustic foam reduces about 25% sound intensity while the rest reduces about 15%. Comparing and contrasting the relations between data might show a trend, suggesting other potential factors. For example, in each material group, the reduced percentage is about the same shown by mineral wool as the acoustic foam. This suggests that the decibel level doesn’t affect the reduced percentage. The odd group is cork with 20% maximum and minimum difference. A plausible major factor is background noise. Since the experiment was executed all at once, the background noise at day one and two might vary up to ∓ 3 dBA reflected in data. Especially in the 64.1 and 70.4 dBA, they are considered on the smaller dBA side that would be amplified more in percentage. Also, the measurement device also has a ∓ 1.5 dBA for accuracy. Additionally, in the whole span of the experiment, two types of carpets are used. It will contribute towards the uncertainty digit (∓ 1 dBA).

Since acoustic foam performs significantly better than all other tested materials, the acoustic foam has some special characteristics. Compared to the other materials, the most distinctive trait for acoustic foam is more exposed holes, also known as porosity (Amares et al. 2017). In general, a material that is more porous will have a larger surface area exposed to sound. When sound tries to pass through a more porous material, the sound will “vibrate” more as it encounters more “wall”, turning more energy to heat energy. Amares’s (2017) study has a similar result, the higher the porosity level, the more effective at sound-absorbing. Another distinctive trait the tested acoustic foam has is irregular surface. This irregularity has increased the exposed area that might help to absorb more sound.

As mineral wool and curtains have very similar results to control, they are not effective material sources. Mineral wool and curtains are synthetic fibrous materials, which are non-degradable and less porous than natural fibrous materials (Arenas and Crocker 2010). This suggests synthetic fibrous materials aren’t as effective as other fibrous materials at absorbing sound.

As for future work, the porosity and the irregular surface factors (Crocker, 2007) can be explored further. Since acoustic foam performs well in this experiment and contains both factors, which of the factors has a larger contribution? Once the more significant factor is determined, further work can be done to develop the more significant factor for greater improvement. Also, most of the sound-absorbing studies have included frequency to show a trend in different factors. Additionally, one major limitation for using percentages is accuracy (Robin et al. 2014) due to the simplification in the measurement process. Sound absorption coefficient is defined as the ratio of absorbed sound energy to incident sound energy (Chelidze, 2018). Sound pressure (dBA), particle velocity (temperature), and media density (air pressure) are three major factors affecting sound energy. But sound intensity is only one factor of sound energy, so the “neglected” factors might contribute to the accuracy. In summary, porosity trait, irregular surfaces can be further experimented with frequency and sound absorption coefficient.

References:

Amares, S, et al. “A Review: Characteristics of Noise Absorption Material.” Journal of Physics: Conference Series, vol. 908, 2017, p. 012005., doi:10.1088/1742-6596/908/1/012005.

Areans, Jorges P. “Chapter 57: Use of Sound-Absorbing Materials.” Handbook of Noise and Vibration Control, by Malcolm J. Crocker, John Wiley, 2007, pp. 696–713.

Arena, Jorge, and Malcolm Crocker. “Recent Trends in Porous Sound-Absorbing Materials.” Sound & Vibration , vol. 44, no. 7, July 2010, pp. 12–17., www.sandv.com/home.htm.

Bardakhanov, S.p., et al. “Hybrid Sound-Absorbing Foam Materials with Nanostructured Grit-Impregnated Pores.” Applied Acoustics, vol. 139, 2018, pp. 69–74., doi:10.1016/j.apacoust.2018.04.024.

Chelidze, Merab. “A New Simple Method for Determining the Sound Absorption Coefficient.” MATEC Web of Conferences, vol. 211, 2018, p. 04003., doi:10.1051/matecconf/201821104003.

“DB: What Is a Decibel?” Physclips, www.animations.physics.unsw.edu.au/jw/dB.htm.

Gracey, Bill. “Acoustic Glossary.” Sound Energy – Acoustic Glossary – Article, www.acoustic-glossary.co.uk/sound-energy.htm.

Hellemans, Alexander. “Soundproofing Drowns Out Deep Noise.” Soundproofing Drowns Out Deep Noise, Science, 8 Sept. 2000, www.sciencemag.org/news/2000/09/soundproofing-drowns-out-deep-noise#.

Hohmann, Beat W.. “Assessment of Impulse Noise regarding Harmfulness to Hearing.” (2015).

Nordin, M.N.A.A, et al. “Research Finding in Natural Fibers Sound Absorbing Material.” ARPN Journal of Engineering and Applied Sciences, vol. 11, no. 14, July 2016, pp. 8579–8584., www.researchgate.net/publication/306185770_Research_finding_in_natural_fibers_sound_absorbing_material.

Robin, Olivier, et al. “Measurement of the Absorption Coefficient of Sound Absorbing Materials under a Synthesized Diffuse Acoustic Field.” The Journal of the Acoustical Society of America, vol. 136, no. 1, 2014, doi:10.1121/1.4881321.

Szalma, James L., and Peter A. Hancock. “Noise Effects on Human Performance: A Meta-Analytic Synthesis.” Psychological Bulletin, vol. 137, no. 4, 2011, pp. 682–707., doi:10.1037/a0023987.