Gulgun (Julie) Ibrahimova, Year 2 Engineering.

Abstract

Electricity plays a major role in everyone’s lives, and more recently scientists have been looking for more environmentally friendly ways to produce it. The topic of this paper is focused on generating electricity by incorporating piezo elements into shoe insoles. The insoles use the alternating current made by the piezo elements and convert it into direct current, which can be collected inside of a battery pack. This device could be of use to those who are far from chargers for prolonged periods of time and need a convenient way to charge their devices. This efficient insole is able to increase the voltage of each battery in the pack of three AA batteries by 0.001 mV after 5 minutes of mechanical pressure on the discs. This shows that despite not being able to generate large amounts of electricity with only 3 piezo elements per insole, the concept of producing clean energy with piezo elements is very possible.

Introduction

Presently, humans are looking for ways to be more sustainable and to create as little pollution as they can, but one of our biggest problems is our electrical energy consumption levels. We use electricity for everything in our day-to-day lives, starting from our electric toothbrushes to our cell phones all the way through to our entertainment systems. Currently, most of global electricity is produced by burning some type of fossil fuel (International Energy Agency, 2018) which contributes to global warming. In order to continue living this lifestyle without harming the earth, there will need to be either some major cutbacks in electricity use or better ways for electricity production. The piezoelectric shoe insole is not the solution to our energy generation problems, but it is a way for people to create cleaner energy for charging their small devices. Piezo element discs, which are made of lead zirconate titanate lined with brass, were used to convert mechanical pressure from footsteps into electricity. The alternating current (AC) made with each step was converted into direct current (DC) in order to be collected in an AA battery pack.

Materials and Methods

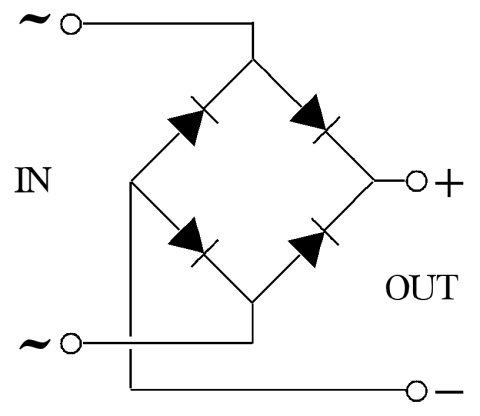

The base of the insole was created by tracing the heel of an ordinary shoe, which was then cut out onto a flexible plastic mat. Then a round drill with a diameter of 2 cm was used to cut out three equal holes in the plastic mat. The purpose of the holes was to ensure that there was space for the piezo discs to deform when a person walks. Next the piezo elements (Audiowell/Amazon) were hot glued directly on top of those drill cut holes. Then four diodes (14N007) were soldered together in a rectangular shape to make the bridge rectifiers that converted AC to DC. Every piezo element needed their own rectifier, therefore 2 more were made (Figure 1).

Figure 1. Bridge rectifiers made of 14N007 diodes

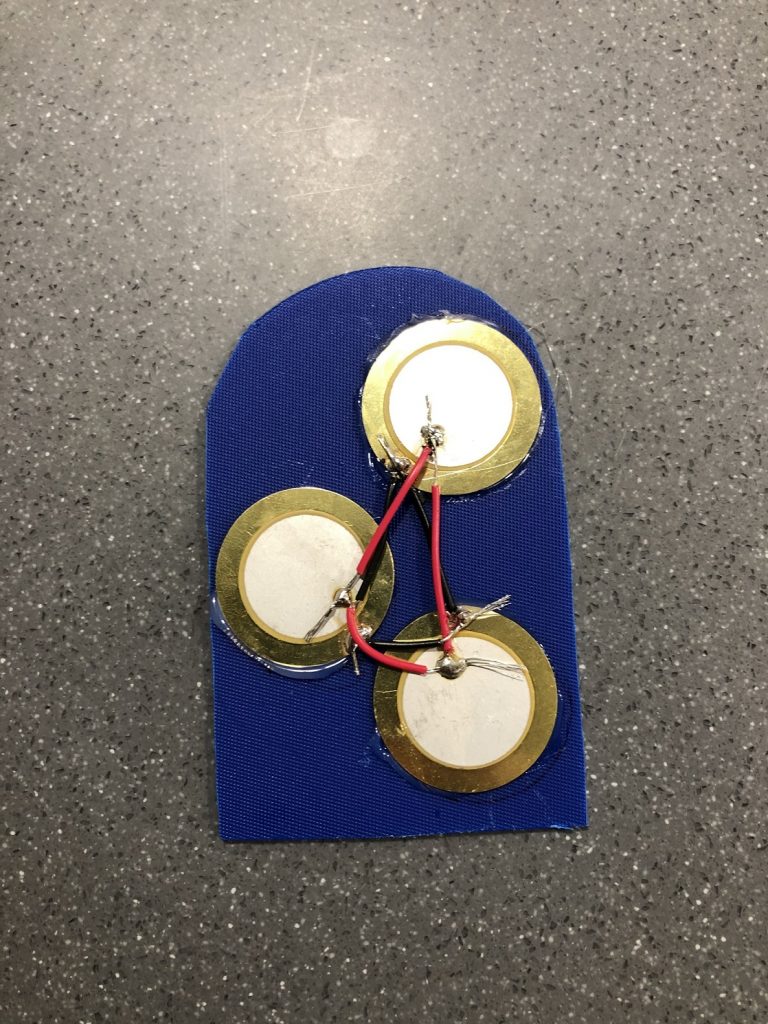

Although piezo elements can create large amounts of voltage, they do not create large amounts of amperage, which is the quantity of charge per second. In order to help with this problem, all three of the piezo discs were soldered together in parallel, meaning the center (positive part of the disc) connected to the centers of the other discs and the outer edge (negative part of the disc) connected to the outer edges of the other discs (figure 2);

Figure 2. Circuit drawing of bridge rectifier. The AC which does not have a specific polarity, comes from the piezo elements. Then the AC is converted into DC, which does have specific polarities, exits and is collected in the battery pack.

this way our batteries could charge faster. Next, the bridge rectifiers were hot glued down, and soldered to each piezo disc with jumper wires, assuring that the inputs of the rectifier were connected to each disc. The polarities were not taken into consideration in this step because the deformation of piezo elements produce both positive and negative currents which is in essence AC (figure 3).

Figure 3. The piezo discs have been connected together to ensure maximum current generation. The centres (positive) are linked together with red wires and the outer edges (negative) are linked by black wires.

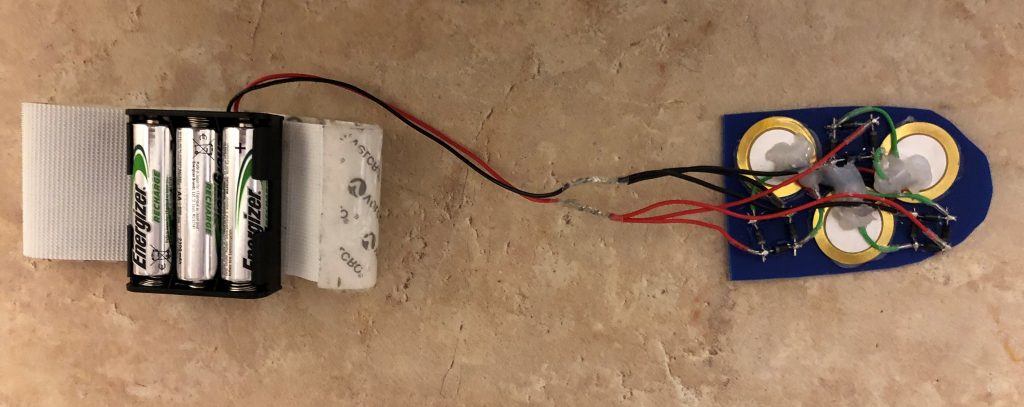

The bridge rectifiers were used to convert AC to DC, and this charge was then collected inside of the AA battery pack, which contained three batteries. Heat shrink and hot glue were placed on connections, to provide insulation and protection. To ensure that it would be comfortable for users, a Velcro ankle wrap was made onto which the battery pack was placed (figure 4).

Figure 4. The final design of the insole

Due to the structure of the insoles it was difficult to wear them not only comfortably, but also without breaking the circuit. The insoles were instead used to prove the concept of piezo elements for the use of electricity generation. The insole was tested by slightly bending the insole with a frequency of about one bend/second, to mimic deformation during human steps. These steps were repeated three times with a duration of five minutes. The voltage of each battery from the pack was measured initially before the beginning of the experiment and after each five-minute session using a multimeter (Mastercraft).

Results

Although initially the purpose was to create a wearable shoe insole, that would generate energy as pressure from the footsteps were generated, it was determined that the insole itself was not durable enough to withstand body weight. Therefore, the rate of voltage generation was measured by adding mechanical pressure to the piezo elements on the insole by bending with hands.

Table 1: Results of Voltage Measurements

| Specific Batteries: | V0 (2000mv) | V1: 5 min | V2: 5 min | V3: 5 min |

| #1 | 1.092 | 1.094 | 1.095 | 1.096 |

| #2 | 1.110 | 1.111 | 1.112 | 1.113 |

| #3 | 1.089 | 1.090 | 1.091 | 1.092 |

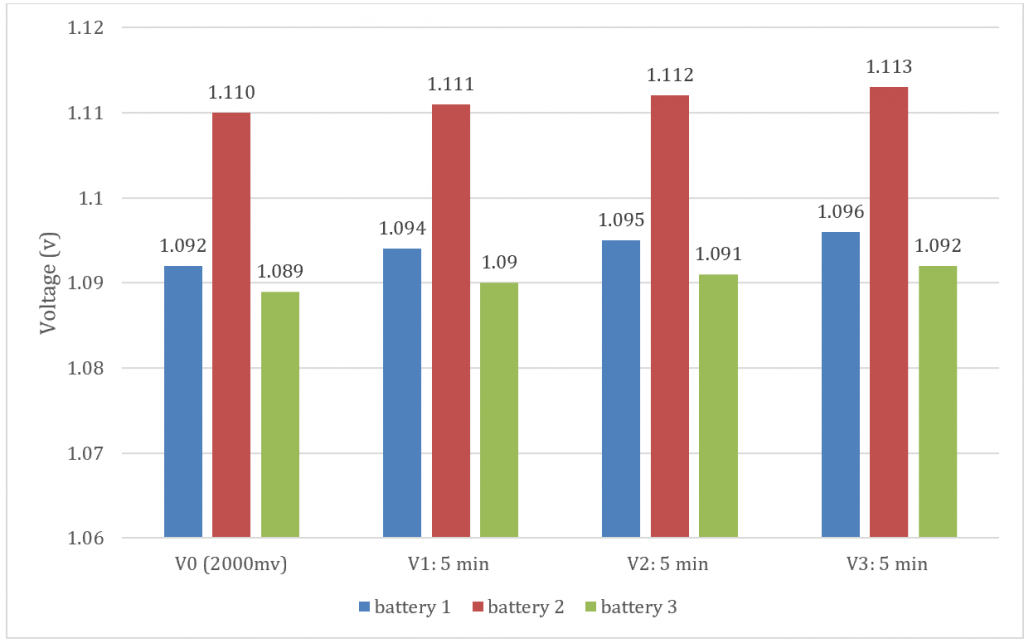

Figure 5. Voltage Production of Piezoelectric Insoles for 3 Consecutive trials of 5 mins of Applied Pressure.

The results of this project showed that with every five-minute testing session each battery in the pack of three increased in voltage by 0.001mV.

Discussion

The findings show that despite the voltage being very small, the piezoelectric insole design is able to generate enough electricity to charge the batteries. However, based on the measurements, it would approximately take 100 hours of walking to charge a 1.2V battery, which is quite impractical seeing that according to the US Surgeon General the recommended walking time per week is 150 minutes (US Department of Health and Human Services, 2015), this would mean that it would take 40 weeks to charge one 1.2V battery. Moreover, if this technology is really going to be incorporated into our lives it will most likely be used for charging handheld devices rather than rechargeable batteries. Since handheld devices need a much greater generating capacity than what three piezo elements can produce, it is safe to say that either people using this insole would have to walk for longer periods of time or the amount of piezo elements on the insole would have to be increased. In addition to not generating large amounts of energy, the insoles were also very fragile and broke easily once they were placed in shoes and worn throughout the day. Due to these reasons, only the concept of piezo elements for the use of battery charging was proven, whereas its application in real life did not meet the requirements. There were also some concerns that the batteries may discharge after some time, though this theory has not been proven, the use of capacitors should be taken into consideration for future projects. Other changes for future designs would include using more piezo discs and possibly adding a protective cover to cushion the wires and make the insole more comfortable. Furthermore, the piezo shoe insole could be used as a portable charger for small devices or even be used to light up shoes during nighttime, which may be useful to pedestrians and bicyclists. The results of this study correlates closely to that of the study by Jingjing Zhao and Zheng You (Jingjing Zhao and Zheng You, 2014). In this experiment the insole produced 2.3mW of power whereas, the insole in the study mentioned above was able to produce 1mW of power. A possible future project would be to create a bracelet that uses electromagnetic induction to charge a battery. The battery would be charged because every time the person moves their arm, the magnet, which would be placed inside of a copper coil, would move back and forth. This would make the magnetic field change and the generated energy would be collected inside of a battery.

References:

International Energy Agency. “Data Tables – Data & Statistics.” IEA, 1 Apr. 2020, www.iea.org/data-and-statistics/data tables?country=WORLD&energy=Electricity&year=2017.

Zhao, Jingjing, and Zheng You. “A shoe-embedded piezoelectric energy harvester for wearable sensors.” Sensors 14.7 (2014): 12497-12510.

HHS Office of the Secretary,Office. “Executive Summary from Step It Up!: Call to Action.” HHS.gov, US Department of Health and Human Services, 8 Sept. 2015, www.hhs.gov/surgeongeneral/reports-and-publications/physical-activity-nutrition/walking-executive-summary/index.html, Apr. 16, 2020.