Xavier Lam, Year 2 Engineering.

Abstract

Due to the buildup of debris, it is necessary to regularly clean out gutters multiple times a year, which can be costly or dangerous for some people. This project aims to solve these problems with a gutter that uses the concept of surface tension to effectively block out debris while containing water. An initial design was created in SketchUp, then a prototype was created using wood, a gutter section and plastic binder covers. The prototype was attached to a roof and tested with different rates of water flow and with debris. The desired results were to have all leaves fall off the ledge and have all water be captured, but the design was unable to fully achieve this. The compromise of the final design allowed the water to flow into the gutter, but also let some leaves in. Ideally, a more accurate simulation of rain would provide better results.

Introduction

Due to the buildup of debris, it is necessary to regularly clean out gutters multiple times a year. If the gutters are not maintained, the exterior and foundation of a building or house will suffer from water damage (White, Jason Michael, and Tom Moor). Additionally, the problem is that it is dangerous to climb up onto the roof to do this especially on a multiple story home or building (“6 Reasons to Clean”). In the US, there are more than 164,000 emergency room-treated injuries and 300 deaths that are caused by falls from ladders (“8 Gutter Statistics”). Home and building owners must resort to hiring professional gutter cleaning companies to do the work, which can cost hundreds of dollars each time (“Learn How Much”). Many homeowners cannot afford to do this. This project aims to solve these problems. The design of the gutter was based on the scientific concept of surface tension and wetting (Surface Tension and Water; ”Wettability.”). The inspiration for this project was the phenomenon called the “teapot effect” is when you pour water sticks/spills down the side of a cup (Ybert, and Bocquet). In my design, the rain will flow down the roofline, around a smooth curve, and back into the gutter, while the leaves fall off the edge of the roof.

Materials and Methods

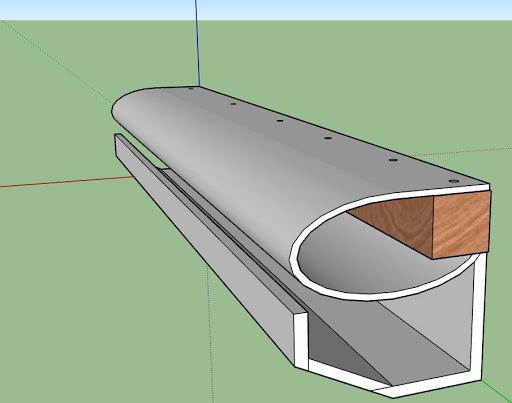

Designing: First, a 3D model of the design was created using SketchUp CAD software (see Figure 1).

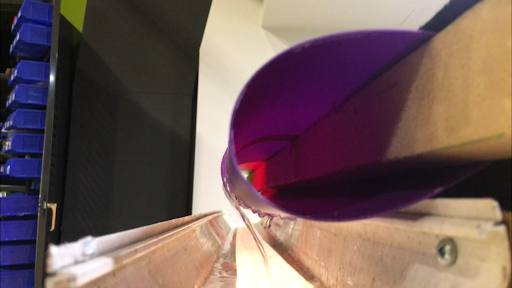

Building: To create the gutter design section, several plastic binders, a 2×2 inch (5.08×5.08cm) plank of wood and a standard plastic gutter section were used. The original plan was to use a 3D printer to print the design of the gutter, however the large scale of the roof and the limitations of the printer did not allow for that. Instead binder covers were used. The plastic binders were cut apart and wrapped around the plank of wood, then secured with screws and duct taped at the seams. The standard gutter part was then secured with screws to the wood plank at a slight angle to allow water to flow out one side. A 2×4 ft. (0.60×1.21 m) roof section with a 7/12 roof pitch was constructed to test the design. The roof section was built using 3 2-inch x 4-inch x 8 ft. (5.08-cm x 10.16-cm x 2.43 m) wood boards, a bundle of charcoal laminated roof shingles (GAF Marquis WeatherMax®), and 5/8 Inch (1.5875 cm) 2×4 ft (0.60×1.21 m) spruce plywood (Goodfellow), using nails, screws, a hammer, and power tools. The gutter section was then attached to the roof. (see Figure 2)

Testing: A 250 ml plastic graduated cylinder was used to pour water by hand at a point on the top of the roof. Three different rates of pouring were tested to simulate different speeds of rain: 250 ml of water in 5, 10, and 15 seconds. The rates were calculated using an online rain calculator (“Volume of Rainfall Calculator.”; Perlman, Howard, and Usgs) The gap between the edge of the dropoff of the design and the gutter section were tested with a 0, 1, and 2 cm gap. To capture the water, a large bucket was placed at the end of the gutter and another bucket was used underneath the area where the water was poured. Debris consisted of dried leaves from trees, and was placed at the edge of the roof. Qualitative data was recorded on the ability of the design to capture water and expel debris. (see Figure 3)

Figure 1. SketchUp model for gutter design

Figure 2. Gutter design with roof

Figure 3. Gutter design prototype with water flow

Results

The desired results were to have all leaves fall off the ledge and have all water be captured, but the design was unable to fully achieve this. The compromise of the final design allowed the water to flow into the gutter, but also let some leaves in. From my results, the design was most efficient with a 1cm gap at a moderate rainfall, however, for lighter rainfall, a gap of 0cm was also successful. In the 1cm gap, some leaves enter the gutter. The 2cm gap was ultimately inefficient as a majority of the leaves would enter the gutter.

Table 1.

| 0 cm gap | 1 cm gap | 2 cm gap | |

| 250ml/5sec (heavy rainfall) | Majority of water is not captured, debris falls off | Majority of water is not captured, some debris falls into gutter | Most of water is not captured, majority of debris falls into gutter |

| 250ml/10sec (moderate rainfall) | Most of water is not captured, majority of debris falls off | Majority of water is captured, majority of debris falls in | All of the water is captured, debris falls in or doesn’t move |

| 250ml/20sec (light rainfall) | Majority of water is captured, majority of debris falls off | All of water is captured, majority of debris falls in/doesn’t move | All of water is captured, all of debris falls in/doesn’t move |

Discussion

My design was able to incorporate the idea of surface tension, but was not 100% efficient. Originally tests of multiple roof angles as well as different shapes for the design were planned, however lack of time restricted this. My methods of testing were limited to using a graduated cylinder to pour water at one concentrated point at the top of the roof which may not have been at a steady rate due to human error. Equipment or access to continuous flow of water over the full surface of the area could be possible future tests. Furthermore, with more accurate simulation of rainflow such as field testing in actual rain, the success of the results could be gauged better and could negate problems with water flow. The less velocity the water had when reaching the edge, the more likely it would flow into the gutter instead of overshooting it. The binder covers worked as needed, however the flexibility of the material could have created inconsistencies in the design. Future work could be done to account for weather such as ice and snow, or the size of leaves and debris. Additionally, more work could be done to incorporate wettability or surfaces of different materials which would affect the water’s velocity.

References

“6 Reasons to Clean Your Gutters: The Importance of Gutter Cleaning.” We Clean Gutters LLC, www.wecleangutters.org/gutter-cleaning-service/.

“8 Gutter Statistics.” Town Building Systems, 26 Feb. 2019, www.townbuildingsystems.net/blog/gutter-statistics.

Amount of rain and area. “Volume of Rainfall Calculator.” CalcTool, www.calctool.org/CALC/other/default/rainfall.

“Learn How Much It Costs to Clean Gutters & Downspouts.” HomeAdvisor, www.homeadvisor.com/cost/cleaning-services/clean-gutters-and-downspouts/.

Perlman, Howard, and Usgs. “Rainfall Calculator, Metric UnitsHow Much Water Falls during

Surface Tension and Water, www.usgs.gov/special-topic/water-science-school/science/surface-tension-and- water?qt-science_center_objects=0#qt-science_center_objects.

“Wettability.” Wettability – an Overview | ScienceDirect Topics, www.sciencedirect.com/topics/materials-science/wettability.

White, Jason Michael, and Tom Moor. “Why Is Gutter Cleaning so Important?” Orange County Register, Orange County Register, 23 Aug. 2016, www.ocregister.com/2016/08/23/why-is-gutter-cleaning-so-important/.

Ybert, and Bocquet. “Beating the Teapot Effect.” ArXiv.org, 17 Oct. 2009, arxiv.org/abs/0910.3306.